Our fabrics and membranes for tensile architecture have excellent specs and withstand exposure to numerous severe conditions that could permanently damage the fabric. Sioen membranes show outstanding performance and technicity thanks to the dedicated engineering.

Our top coats provide good cleanability, good processing and they are an efficient barrier for plasticizer migration and weather impact. They are a balanced compromise between optimised weldability, excellent weathering resistance and long lasting aesthetics, among others.

This innovative generation of patented top coats was created by our 200-headed R&D department in cooperation with the Sioen Chemicals Division.

All our architectural membranes are directly weldable without preparation, which guarantees perfect seams. In addition, our low wick treatment contributes to maintain robust seams throughout the structure’s life time.

Thanks to our unique PVDF lacquer, our membranes have excellent dirt resistance and durable easy cleaning properties. Our Fluomax and Fluo²max membranes are even lacquered on both sides.

Thanks to the new TiO₂ prime coat barrier, our Fluo2max membrane achieves outstanding UV resistance in permanent structures.

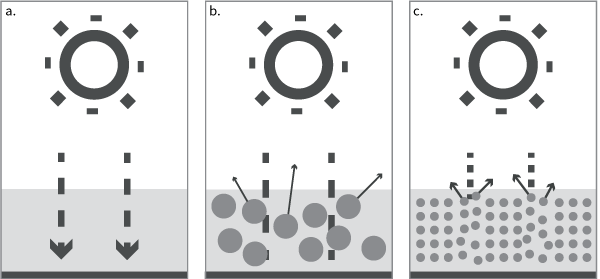

TiO₂ has been known as an excellent UV barrier for decades. Even if it is used in an extremely thin layer, it already offers a very efficient UV protection. That is why it is also used as a sun blocker in cosmetics.

The combination of the TiO₂ technology and the Fluomax PVDF top coat results in a highly innovative coating that blocks all UV radiation. Therefore, the membrane lasts very long and we can offer you a 20 year warranty.

a. Chemical UV Filter

No particles

b. Standard TiO₂ Technology

Coarse particles

c. Sioen TiO₂ Technology

Nanoparticles

Thanks to our membranes’ low wick properties, the mechanical and aesthetical properties are preserved. Wicking is the migration of water between the filaments of the fabric. It occurs when the woven base fabric is directly exposed to extreme humidity and it can result in fungal and bacterial growth.

The phenomenon initially results in an aesthetical appearance that looks poorly, as yellowish, brown lines and stains appear all over the base fabric and at the seams. In very bad cases, the physical performance of the fabric decreases and might lead to structure failure.

Fortunately, Sioen membranes undergo our in-house low wick anticapillary treatment, which prevents wicking. The treatment successfully avoids all water, dirt and fungus absorption inside the fabric and ensures long lasting aesthetics, minimal discoloration and uniform translucency.

All building materials should comply with the local and international safety regulations. One of the most important properties is the ability of the membrane to avoid fire initiation and propagation over the building structure.

All tensile architecture fabrics are produced using high quality flame retardant additives in order to achieve appropriate flame retardant performances recommended by the building industry. Our materials meet the required specifications, as they are self-extinguishing, they have low flame propagation and have no flaming droplets.

The ability of a fabric to burn or ignite, causing fire or combustion, is quantified in fire standards. Internationally, there is a variety of test protocols to evaluate the flammability of a textile material. All Sioen membranes comply with the following fire standards: DIN 4102; EN 13501-1; NF P92-507; BS 7837 and with the California Code of Regulations.

Our Sioen membranes are sold and used in structures all over the world. That also means that they are used in many different climates and temperatures.

Luckily, our architectural membranes have a temperature resistance ranging from -30°C to +70°C. The material remains flexible, even at a low temperature. That way, it can be easily handled and installed.

Light is of major importance in life. In architectural constructions, the duality of light and darkness is a challenge for each and every construction engineer and architect. We help you find the right balance.

Our Sioen membranes offer you the exceptional advantage of combining structural design with an abundant presence of natural light. Thanks to the membrane’s very high translucency, a natural feeling can be created.

The membranes can be used for visual effects with, for example, communicational or architectural designs on it, thanks to its uniform translucency. It is guaranteed through a consistent measurement of the batch to batch colour translucency deviation. The interior/ exterior luminosity can transform the structure into a signage structure or a nocturnal reference point.

We offer a solution for every need. By using tensile membranes for your building structures, you can improve the thermal performances and the energy balance.

Thanks to combining different fabrics, the energy management can be monitored and controlled. To insulate the structure double membranes are used. The insulation profits from the combination of incident radiation and the insulating air gap between the two membranes.

Our opaque membranes also offer designers the ability to reduce the high radiation flux. In addition, Sioen also offers low emissivity membranes with the lowest emissivity on the market (e = 0.22). The use of Low E membranes in textile architecture ensures optimal thermal comfort for the final customer.