We make sure that our products’ lifetime is prolonged through a dedicated design for durability and through the possibility to repair and recycle products. Reliable and durable membranes provide value for money and prevent overuse of resources and waste.

With the help of the technical and chemical experts of our R&D-team, our durability approach should help protect our planet from over-exploitation.

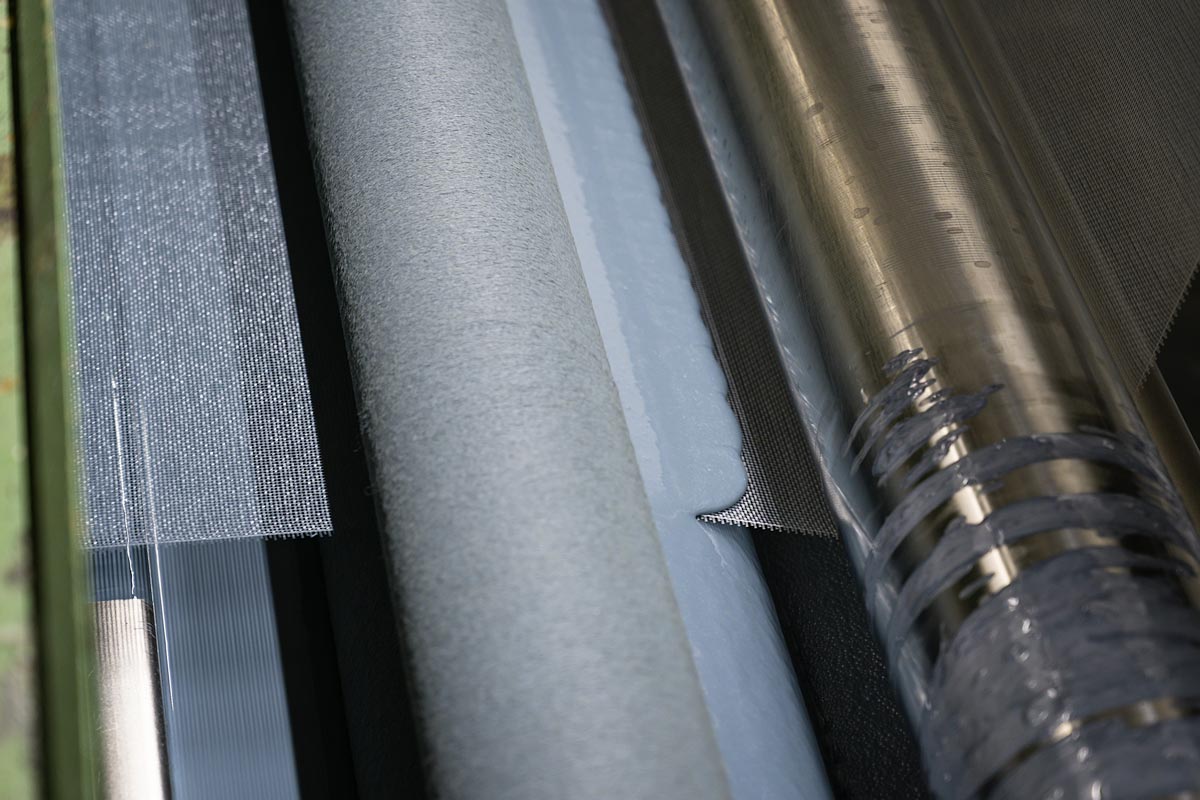

The range of Sioen Tensile Architecture membranes is produced according to 4 cutting-edge technologies, each one of them contributing to sustainable and durable membranes.

The Facade range is the result of thorough research and development and decades of expertise in dip-coating. In addition to our in-house engineered integrated weaving and coating process, we use a unique lacquering system that perfectly embeds the scrim, ensuring homogeneous coverage of the scrim. This in turn guarantees better durability. It contributes directly to the reduction of the use of resources (raw materials, gas, electricity, …) and of waste.

The Sioen Flexout range is engineered on our transfer coating lines with the aim of creating a longer lasting fabric. A flexible material used outdoors has its limits and can only be as flexible as it gets. Decades of R&D, lab and outdoor testing resulted in a flexible range for stretched structures and tents that last way longer thanever before. This better reliability is reassuring, reduces the cost and contributes to a better world.

The Sioen Fluoscrim range is the result of in-house engineered complexing of film sand in a fabric. The life expectancy easily exceeds decades . A longer lifetime implies less replacement and has direct consequences on the environment because less raw materials and less energy are needed, additionally less waste is produced.