Developing and manufacturing qualitative products is one thing, cleaning, maintaining and repairing them another. It is important to clean your membranes in the right way. Furthermore, we offer maintenance and repair services to further extend your product’s life.

General

Thanks to its excellent lacquer properties, Sioen membranes will hardly collect any dirt on the outer surface, as it can mainly be removed with rain water. The inner surface, however, has to be cleaned by hand using the following recommendations:

The frequency of cleaning depends on the surface’s optical requirements, and it may differ depending on the type of project, the chosen fabric and the location of the structure.

The cleaning of the membrane can only be done by a professional company and the manufacturer’s cleaning regulations have to be followed. In case the regulations are not strictly followed , your warranty might not be granted.

The owner of the construction has to make sure that the cleaning regulations are handed over before the cleaning starts, as the cleaning company has to follow the manufacturer’s regulations.

The fabric surface, roof area and edges should always be accessible for cleaning and repairing. A movable scaffolding system has to be installed for all tasks mentioned before.

Please work safely at all times. Not considering safety measures, might be dangerous for the workers, and it could harm the fabric. Please do not put any pressure on tension devices, cables, clamps or rigging screws without consulting the project documentation and without contacting the membrane specialist.

In case of damage, please inform Sioen Industries NV immediately.

Protection, precautions and safety measures

All safety measures for working at heights should be followed while cleaning the fabric. People without the right specialisation should not be permitted access to the fabric encasement and all its components. Please keep in mind that you should prevent heavy, hard or sharp objects from falling on the fabric. The cleaning staff certainly has to take adequate protection precautions.

Cleaning materials

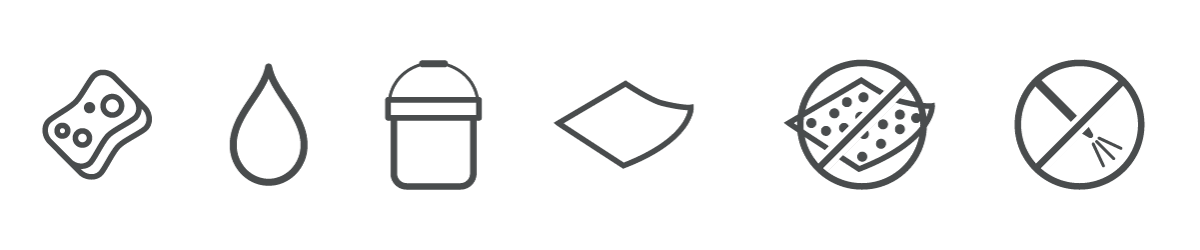

Exclusively use soft and sponge textile cloths with water for cleaning the fabric. Washing liquid can be added to the water. Rough cleaning cloths are not allowed, as they may lead to scratches on the fabric’s top coat. The use of pressure or steam cleaners is not allowed.

Cleaning agents

Aggressive cleaning agents are not necessary. In general, solvent-free non-alkali gentle soaps with a pH value of five are used.

Please remove coarse dirt and foliage from the entire roof surface and profiles before cleaning the fabric surface.

Subsequently, sand, dust and other rough particles should be rinsed off with clear water.

Then, the properly thinned cleaning agent is added. The appropriate cleaning instruments are used for the whole PVC/PES membrane surface. Use circular movements and only use very gentle pressure.

After approximately ten minutes, the cleaning agent can be rinsed off with clear water.

You should not dry the surface with hot air or make it too hot, as that may lead to changes in colour.

Always provide safe access to the site and take care of environmentally friendly detergent water evacuation.

Depending on the fabric system, other elements such as cables, fittings, turnbuckles, etc. may generate corrosion and staining may occur. Carefully use a mild abrasive liquid cleaner to remove it. Make sure that those cleaning agents do not touch the fabric.

Cleaning frequency

The cleaning frequency mainly depends on the environmental conditions of the respective application area.

Nevertheless, the fabric surface should not be cleaned more than once a year. During this process, it is recommended to clean and/or repair all other structure elements at the same time.

Unlike conventional roofs, the maintenance intensity of our materials is very low. In case of doubt about any particular process or cleaning solution, please do not hesitate to contact us.

Making things well is one thing, having the ability to repair them is another. Repair requires particular characteristics of the membranes and a thorough understanding of the composition of all elements. Our product designers and engineers take this repair requirement into the equation. After all, you do not just want a great tensioned structure today. You want it to be great for a long time. That is why, in addition to the durability of our membranes, the possibility of repairing them is an extra asset.

Our lab-experts have developed smart clean & care instructions and repair tips & tricks that are tested on the field ever since the early seventies of the previous century. The end results make everybody happy: durable textiles and membranes that fit their purpose, whether it is sun shading, facade or a tensioned structure.

Repairs

Fabrics can be cut, torn or damaged in other ways by sharp objects. The fabrics can even be crushed if heavy objects or other damaging elements, such as sharp edged cables, fall on their surface. Small cuts can be repaired by specialists with hot air welders. Patches can be applied directly on the damaged area. In case of large damages, it may be required to replace the entire panel.

Inspection plan

Throughout the structure’s lifespan, visual inspections for obvious damage or for deficiencies should be performed.

It is mandatory to inspect the fabric in order to detect and report minor deterioration regularly. The exposed surfaces are subject to dirt and fungal accumulation, especially when they are not maintained well. It might lead to poor aesthetics and, in extreme cases, to physical deterioration of the material properties.

The regular checks consist of performing visual inspections of the membrane in order to check the performances of the fabric. You should check whether there is/are:

no tears on the surface or alongside the edges;

no peeling or delamination at the welded joints;

no heavy dirt build-up on the surface (dead leaves, insects, ashes, fungal composition or any other permanent dirt).

A permanent safeguarding of the mechanical as well as the physical condition of the membrane is mandatory.

The fabric should be inspected at a regular frequency. The right frequency is mentioned in the maintenance plan. Normally, an inspection should be done every six months in order to detect minor damages that could turn into major damages if not repaired soon enough.

Special inspection should be done after:

heavy storms with extreme winds

heavy snow fall or hail storms

accidental falls of external elements onto the fabric surface

exceptional events of any kind that influence the stability of the fabric

any partial or general replacement of any of the system elements