At Sioen, we try to be as responsible as possible, both socially as environmentally. We want to contribute to solving the challenges our environment faces today, such as finding alternative sources of energy, using less raw materials, reducing waste and emissions, etc.

Our production process involves waste that is mainly reused and/or recycled. At its end of life (EOL), the technical textiles can also be recycled.

We recycle raw materials in all the steps of the value chain in producing a Sioen membrane for tensile architecture, tents, halls and façade cladding:

On our state-of-the-art Sioen extrusion lines we produce 18.000 tons of high tenacity polyester yarns, with a no-waste policy.

More than 500 weaving looms are operating 24/7 to manufacture your fabric for tensile architecture applications.

We produce 14.000 tons of PP with a no-waste policy.

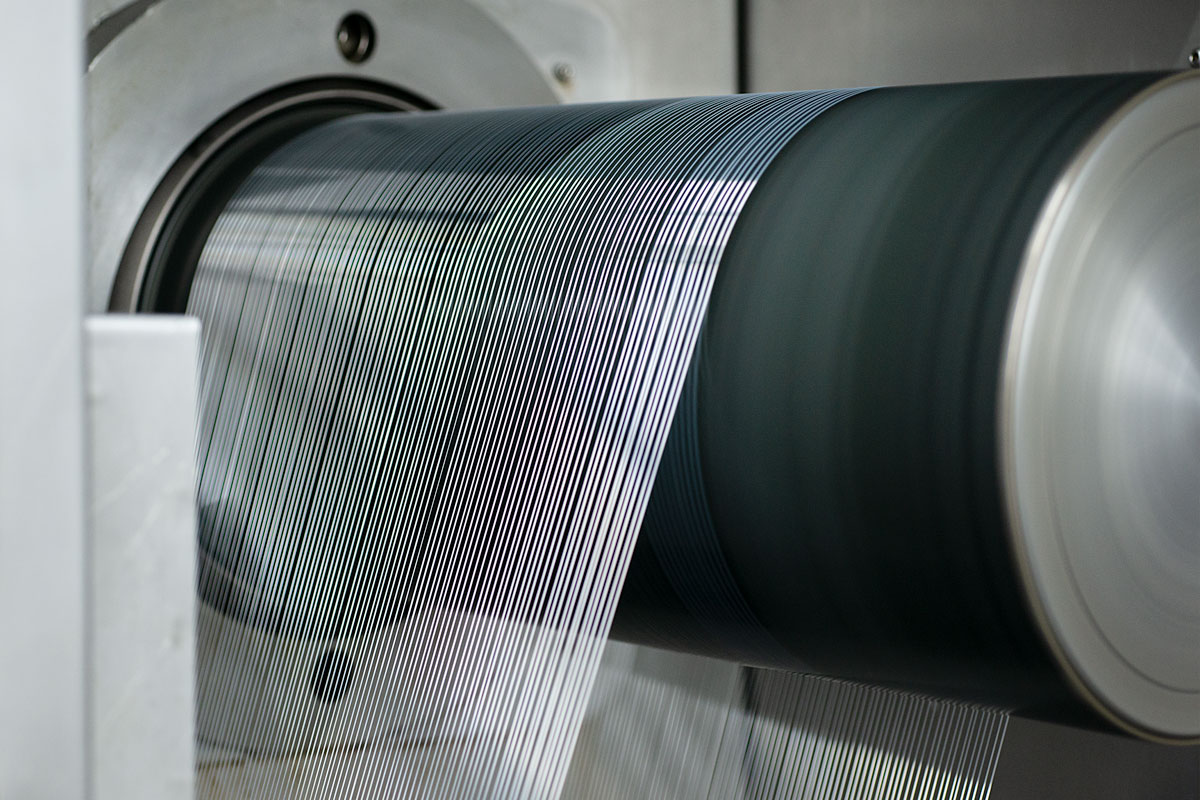

Our calendering line produces films and foils with a zero-waste tolerance:

While producing our Sioen pigment pastes and colouring solutions, we recycle and reuse all of our cleaning agents. The rest paste is accumulated and used in special batches for ground layers for third party products, such as mud flaps.

Our coated technical textiles are engineered to last longer. We build our fabrics so that they can easily be repaired. When at the end of its initially intended life, it often gets a second life as a base fabric for a.o. bags or tarpaulins to cover wood or other stacked things that need to be kept dry.

When the time comes that the coated fabric is definitely end-of-life, there are various options.