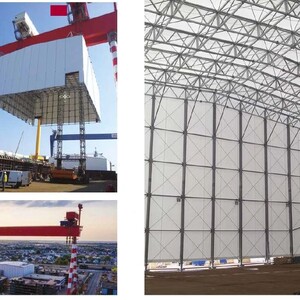

Enhancing Shipbuilding Efficiency: The Advantages of Lightweight and Moveable Hangars

Lightweight and mobile hangar for shipbuilding industry. Crafted from standardized aluminum profiles and wrapped with durable coated textiles

- Nantes, France

- Fluomax Type II - T2118F

- 11 000m²

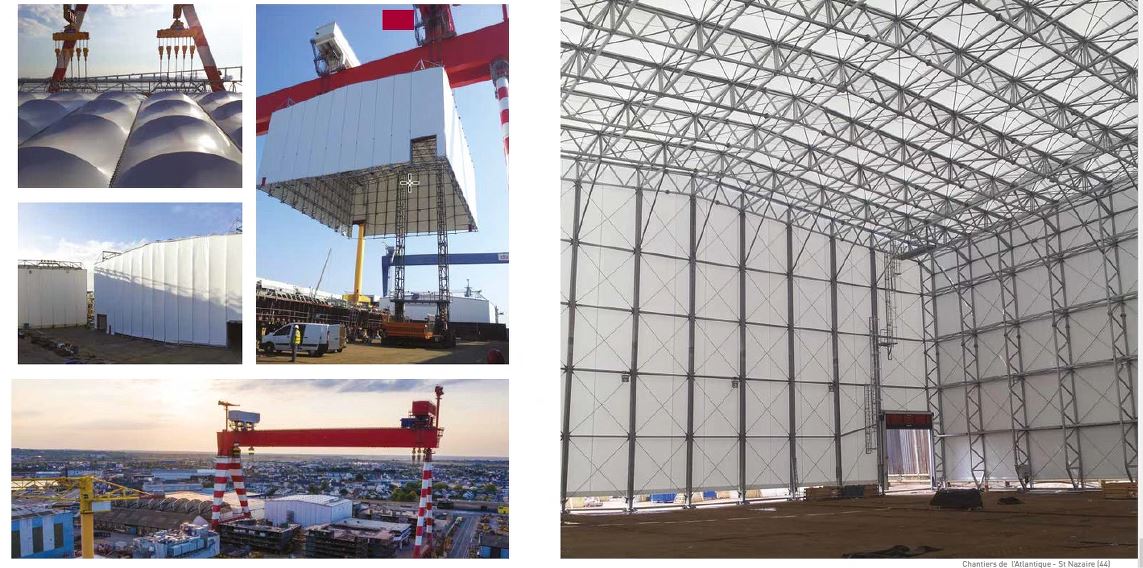

In the dynamic world of shipbuilding, efficiency and quality are paramount. A pivotal innovation in shipbuilding plants comes in the form of lightweight and moveable hangars. These expansive structures, made from standard aluminum profiles and wrapped with durable coated textiles, offer a myriad of benefits that significantly elevate the shipbuilding process.

Huge moveable hangar in St Nazaire shipyard wrapped with Fluomax T2 fabric

First and foremost, the lightweight nature of these hangars facilitates seamless mobility within the shipyard. Their aluminum framework ensures structural integrity while keeping overall weight minimal, enabling swift relocation to different areas of the shipyard as needed. This versatility allows shipbuilders to optimize their workspace, adapting to varying project requirements without delay.

Protect people, work and belongings with lightweight fabrics

Moreover, the moveable hangars serve as a shield against the unpredictable forces of nature. During the production and painting phases of shipbuilding, exposure to environmental elements can jeopardize both the quality of work and the safety of personnel. However, these hangars provide a protective barrier, shielding the work area from adverse weather conditions such as rain, wind, or excessive sunlight. By maintaining a controlled environment, the hangars safeguard the integrity of the ship under construction, ensuring meticulous craftsmanship and adherence to quality standards.

Providing unique solutions for the future of the industry

Additionally, the moveable nature of these hangars enhances operational efficiency. Shipbuilders can seamlessly reposition the hangars to accommodate the workflow, minimizing downtime and streamlining the production process. This agility not only expedites project timelines but also optimizes resource utilization, ultimately reducing costs and increasing profitability.

The lightweight principles: towards more eco conscious solutions.

Furthermore, the lightweight materials used in constructing these hangars contribute to sustainability efforts within the shipbuilding industry. Aluminum, known for its recyclability and low environmental impact, aligns with the principles of eco-conscious manufacturing. By investing in lightweight and durable hangars, shipbuilding plants demonstrate a commitment to responsible stewardship of natural resources, while simultaneously improving operational efficiency.

Find the Environmental Product Declaration of our product here:

https://epd-online.com/EmbeddedEpdList/Download?id=18770

In conclusion, the integration of lightweight and moveable hangars revolutionizes shipbuilding operations, offering a plethora of benefits ranging from enhanced mobility and environmental protection to increased efficiency and sustainability. As shipyards embrace these innovative structures, they not only elevate the standards of craftsmanship but also pave the way for a more resilient and efficient future in maritime construction.

Up next